All Designs, Videos and Prints, created by Swimwear Bali

We Handle All

At Swimwear Bali, we manufacture luxe-quality sustainable Swimwear, partnering with startups and established brands globally. We’ve built our reputation on fabric quality, great prices, attention to detail, and quick, timely communication.

The fabrics we incorporate into your collections are not just sustainable; they are a testament to our global commitment, produced from post-consumer waste, reclaimed fishing nets, and plastic bottles by REPREVE® in the US & Carvico® & ECONYL® in Italy. All offer UV 50+ and chlorine protection, superior body-enhancing characteristics & a super soft hand feel., imported under our Tax-Free bonded facility, saving 35% that all other Bali Swimwear manufacturers must add to their costs & ultimately, your invoice values.

With a keen eye for current trends and some social media skills, you are already halfway to owning a successful sustainable Swimwear brand.

We are here to guide and support you every step of the way with comprehensive advice and guidance via email, WhatsApp, or free online consultation, just a message away, ready to help you bring your vision to life.

With every order, you’re making a significant difference in the lives of Bali street kids. We proudly support a charity run by Kim from New Zealand, dedicated to providing safe houses and a better future.

Contact Kim via WA.

If you’re starting from scratch, you’ll find everything you need in our comprehensive Starter Packs. These packs include a variety of high-quality fabrics, design templates, and expert guidance to help you kickstart your sustainable Swimwear brand.

Swimwear Bali, turning dreams into reality.

MOQ

We offer a low MOQ of 300 pieces per PO in as many designs as you like, for example, 150 bikini sets, 30 pcs per design, three pieces per size, colour & print.

Custom Swimwear

As a specialist custom swimwear manufacturer, we can produce almost any design on request.

With 30+ years of experience, we’ve developed a tried-and-trusted system of assembling luxe Swimwear at the lowest price in the shortest time.

Any design can be made in any fabric colour or print.

If you’re ready to unleash your creative juices, running your own business, living the dream, we’re here to help make that a reality.

With our ready-to-order collection, we incorporate the most popular shapes from our previous collections as well as upcoming trends selling hard & fast until late 2024. Our industry expertise gives us insight into the shapes and colours ordered months in advance by some of the most prestigious brands.

Choosing some or all of your shapes from our designs is a great solution for those seeking some inspiration & entrepreneurs starting their own sustainable swimwear label.

Our Philosophy

We believe you should feel confident and comfortable as well as look amazing in our swimwear

Example Prices

Prices below all-inclusive to the finished articles using imported recycled fabrics

Typically, our Swimwear has a resale value of approx 4.5 times our wholesale price.

For example, a bikini top at USD 13.00 retails for USD 59.00. A bulk order with us for 300 units, or Bikini 150 sets, for example, only buys 200 units or 100 sets from any other Bali Swim supplier.

How To Order

Be clear on your designs

The first step is to choose the designs you want to produce. These can be your custom designs, our ready-to-order ones, or a mix of both.

We price custom designs very similarly to our ready designs.

Choose your colours

Next, decide whether to use our stock colours or request custom colours to be dyed and imported. This choice will affect the number of colours you can add to your bulk order and the required production time.

We hold 85 on-trend colours in total, ready to cut on demand & note that our stocks are not leftover; they are flown in as soon as bulk orders are cut.

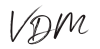

Adding Prints

If you love prints, you’re in a good place. We print on super-soft REPREVE from the US using MS Machines from Italy and fly them in weekly. We require your artwork in Vector format in EPS, PDF, CDR, JPEG format, high resolution 300 dpi, and scale. If you require some assistance, our graphics team is here to help, in most cases free of charge.

Read more to Add Prints

Pricing your collection

The final step is to determine prices. We are the lowest-priced manufacturer in Bali, producing the highest-grade product incorporating imported recycled fabrics. Establishing prices early on, lets you calculate your expected markups and profits before investing in samples.

Click the link below to price your designs.

Sampling

Quick Turnarounds

We are proud to offer the fastest sample turnaround times in the industry, starting at just seven days. If you provide us with clear and concise design handovers, we can produce patterns in as little as 72 hours and have samples ready to go within a week – depending on the level of complexity. We are committed to delivering high-quality products quickly and efficiently.

Note

Timelines vary according to whether you’re selecting from our stock colours or requesting imported colours or prints, time of the year, etc.

Our customer liaison team will offer our fastest turnaround time on request.

Read More about Sampling

Sample Fees

We offer two types of design options – Ready-to-Order (RTO) designs and Custom designs.

RTO designs are meticulously crafted and priced at two times our wholesale price. For a $30 fee, you may request slight modifications to our designs.

Custom designs are charged twice the marked price plus a $30 management fee. Your design concepts are seamlessly translated into samples, and any apparent discrepancies are rectified free of charge.

We edit the patterns for minor adjustments using our 2D Auto CAD digital pattern maker.

Selecting Plain Colours

Colors can be chosen from 85 trending stock colours or imported in 70m rolls. New brands typically use stock colors, while established brands mix stock and imported colors. One roll produces approx 200 bikinis (or 100 bikini sets) which can reduce the number of colours in your PO.

Selecting stocks allows top-up orders produced much faster than having to import your colours. Stocks are not leftovers; we fly them in when bulk orders are cut.

Colours Example

Adding Prints

We offer real digital printing on nylon & sublimation printing on polyester, printed overseas due to colour saturation more true to life with colours never fading when exposed to salt or chlorine.

When time is short, we use Vita PL, a polyester version of Nylon Vita. Moreover, printing is faster and easier than plain dyeing. In order to save time and money, we recommend purchasing ready-made prints from sellers such as Shutterstock.

Print Example

Sustainability

Almost all of our fabrics are made from salvaged fishing nets and plastic bottles sourced from Italy, Korea, and the United States. Surfer Kelly Slater played a crucial role in transforming ocean waste into these sustainable fabrics. With recycled fabrics, your brand can rightfully claim it is ethically and sustainably produced by reducing its carbon footprint by up to 80%.

USING RECYCLED FABRICS OVER NEW

Customer Reviews

Have Question's?

Having served the swim industry for 30 years, we know how to build brands effectively and efficiently. With our proven tips and strategies, we’ll show you how to build a brand that stands out while saving time and money. Let’s create a brand that truly reflects your ethos and captures your target audience’s attention.